DF-(P)DGS6

DF-(P)DGS6

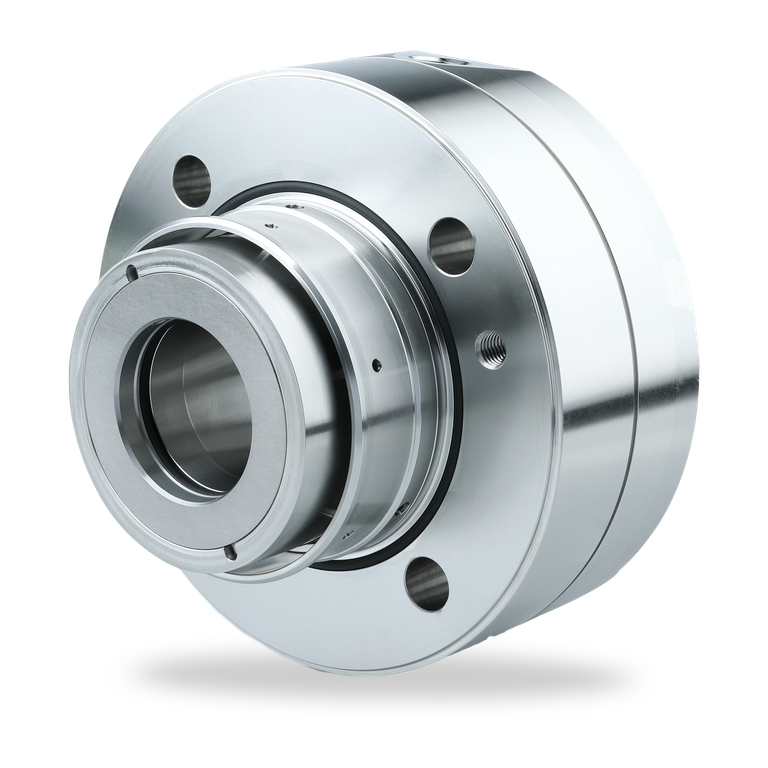

DF-DGS6 Tandem seal

with intermediate labyrinth

with intermediate labyrinth

| 1 | Seal face |

| 2 | Seat |

| 3 | Thrust ring |

| 4 | Spring |

| 5 | Shaft sleeve |

| 6 | Intermediate sleeve |

| 7 | Housing |

| 8 | Clamping sleeve |

| 9 | Set screw |

| 10 | Adapter |

| 11 | Process side labyrinth |

| 12 | Internal labyrinth |

| F | Flush - optional |

| CSV | Containment seal vent |

| CSD | Containment seal drain |

| GBI | Gas buffer inlet |

DF-(P)DGS6

Features

- Dry gas seal for multiphase pump applications

- DiamondFace sliding surface technology

- Ideal for applications with Ethane, CO2, and similar media with low vapor margins

- Shrouded rotating ring

- Bi-directional

- Ready-to-fit cartridge unit

- Single, double, tandem, and tandem with intermediate labyrinth available

Advantages

- DiamondFace sliding surface technology for maximum operational performance under multiphase process conditions (liquid, vapor, supercritical)

- Ideal upgrade solution for wet mechanical seals with dry running issues

- Simple set-up: seal gas heating and nitrogen buffer are not required

- Stiff sealing gap creates necessary heat and doesn´t require additional heating

- Significantly lower leakage rate avoids icing problems with CO2 (Joule Thomson effect) and keeps emission rate low

- High film stiffness in all operating modes

- Proven reliable and economical solution

- Adjustable to extreme narrow installation space - retrofits are easy to implement

Materials

Primary seat and seal face: Silicon carbide with DiamondFace technology

Secondary seat and seal face: Silicon carbide with DLC coating (optional: DiamondFace technology)

Secondary seals: FKM, FFKM, PTFE (DF-PDGS6). Other elastomers available, depending on product gas composition

Metal parts: 1.4006 (410) and other stainless steels

Secondary seat and seal face: Silicon carbide with DLC coating (optional: DiamondFace technology)

Secondary seals: FKM, FFKM, PTFE (DF-PDGS6). Other elastomers available, depending on product gas composition

Metal parts: 1.4006 (410) and other stainless steels

Standards and approvals

- NACE

Recommended applications

- NGL (Natural Gas Liquids) processes

- Flashing hydrocarbon applications

- Liquid and supercritical CO2-applications

- Oil and gas industry

- Refining technology

- Petrochemical industry

- LNG

- CCUS

- Hydrogen

- Power generation

Notes

Dimensions on request.

Sealing CO2 reliably with conventional mechanical seals is challenging due to the difficulty of maintaining the fluid in a phase appropriate for the seal type. With CO2, the phases range from liquid, supercritical to vapor, depending on the process parameters.

EagleBurgmann has performed extensive analysis, calculations, and testing, and developed with the DF-PDGS6 an effective and efficient sealing solution.

In our white paper "Advanced turbomachinery dry gas seal design solution for multiphase CO2 pump applications", we take a closer look at the special characteristics of CO2 and why they effect the safety and reliability of a seal. For more information, please feel free to contact us or download the whitepapger directly.

The DF-(P)DGS6 product brochure can be found in our Download Center.

Sealing CO2 reliably with conventional mechanical seals is challenging due to the difficulty of maintaining the fluid in a phase appropriate for the seal type. With CO2, the phases range from liquid, supercritical to vapor, depending on the process parameters.

EagleBurgmann has performed extensive analysis, calculations, and testing, and developed with the DF-PDGS6 an effective and efficient sealing solution.

In our white paper "Advanced turbomachinery dry gas seal design solution for multiphase CO2 pump applications", we take a closer look at the special characteristics of CO2 and why they effect the safety and reliability of a seal. For more information, please feel free to contact us or download the whitepapger directly.

The DF-(P)DGS6 product brochure can be found in our Download Center.

Recommended piping plans

API Plan 76

Optional:

API Plan 02

API Plan 12

API Plan 13

API Plan 32

API Plan 72

API Plan 75

Not recommended: Plan 11 and plans with cooler e.g. 21, 22, 23

Optional:

API Plan 02

API Plan 12

API Plan 13

API Plan 32

API Plan 72

API Plan 75

Not recommended: Plan 11 and plans with cooler e.g. 21, 22, 23

Product variants

DF-PDGS6

For multiphase pump applications (especially with CO2) with high pressure and both low and high temperature applications (see operating range). With U-cups and special dynamic sealing elements. Secondary seals made of PTFE.

Similar products

SHI300

- Robust seal design - suitable for demanding light hydrocarbon applications

- Compact cartridge seal for small seal chambers

- Single unpressurized seal with a high pressure-non contacting containment seal

- Stationary spring loaded unit

- Balanced primary seal faces in materials with high thermal conductivity and strength

- Multi-point injection of the flush fluid optional

- Seal faces can be equipped with lubrication enhancing grooves and/or DiamondFace technology

SHI366

- Robust seal design – especially for demanding crude oil applications

- Compact cartridge seal for small seal chambers

- Single unpressurized seal with containment high-pressure throttle design

- Stationary spring loaded unit

- Balanced seal faces in materials with high thermal conductivity and strength

- Inserted seal face

- Multi-point injection of the flush fluid optional

- Seal faces can be equipped with lubrication enhancing hydropads and/or DiamondFace technology