The high-end trio for difficult operating conditions

EagleBurgmann international

EagleBurgmann WORLDWIDE

With around 250 locations and 90 serve centers, we are represented in the most important economic regions of the world. The advantages are clear: short paths to our customers, fast response times and a shared language.

Solutions against contamination

Maximum robust sealing technology for turbo compressors

Maximum robust sealing technology for turbo compressors

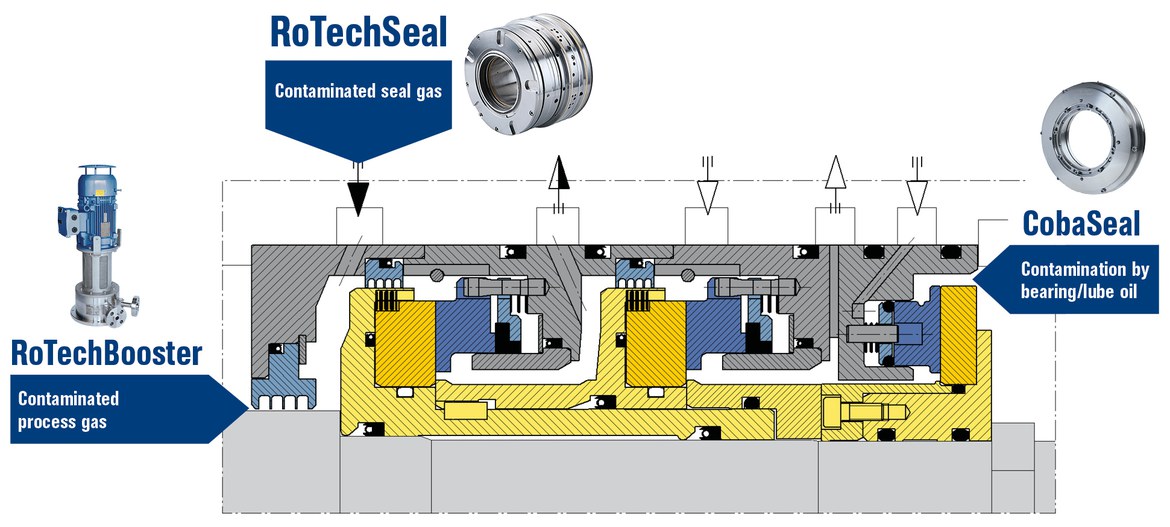

High-end trio against contamination. For maximum operational safety.

Turbo compressors are key components in production plants. Reliable and safe operation at all times is indispensable. Long-term analyses show that only 3.9% of all compressor malfunctions are due to problems with Dry Gas Seals (DGS). However, any unplanned machine failure is annoying and can quickly cause immense economic damage. The number one cause of damage to DGS here is impurity due to contaminated process or supply gas and penetrating bearing oil.

Pictures: That is a problem for every seal - obvious dirt deposits on mechanical seals due to supply gas (left), process gas (center), bearing oil (right)

Anyone who operates compressors and has to contend with impurities must invest an enormous amount of resources in prevention and in damage repair. A permanent risk of failure exists nonetheless. Even small amounts of impurities can cause the DGS to fail.

Dirt deposits in the DGS cause contact between the seal faces or excessive torques which negatively affect safe and reliable operation. This does not have to be the case!

EagleBurgmann has developed innovative products with superior technology designed to reliably repel impurities or react less sensitively to them:

RoTechSeal – DGS with individual technology tuning for increased robustness against contamination from supply gas more...

RoTechBooster – Gas supply unit for protection against contamination from process gas during slow roll and pressurized compressor standstill more...

CobaSeal – Separation seal as protection against contamination from bearing oil more...

RoTechSeal, RoTechBooster and CobaSeal are a technically reliable and economically attractive high-end trio that can cope with any type of contamination in compressor operation. The overall result is excellent performance which ensures significantly increased operational safety and economic efficiency.

Sustainability Board

EagleBurgmann continuously minimizes the impact of its own production processes (footprint) on the environment. At the same time, we improve sustainability for our customers (handprint) with innovative and reliable products.

Our Robust Technology solutions specifically excel in the following:

Emissions:

- Leakage optimization and subsequent reduction of environmentally harmful emissions (RoTechSeal)

Energy:

- Reduced energy consumption, e.g. through reduced nitrogen consumption (CobaSeal)

Waste:

- The products are known for their high quality and long operating periods.

- The solutions are of high quality, enabling long operating periods and increased lifetime. When servicing is required, the products can be repaired and only defective parts are replaced.

>> Continue with the RoTechSeal

We are happy to advise you

Would you like personal advice, do you have any questions or would you like to order directly? We look forward to supporting you.

Robust Technology Inquiry

for further information

Powerful. Reliable. Contamination resistant.

The high-end trio for difficult operating conditions

Excellence in Practice

With our free e-mail newsletter „Excellence in Practice“, you will receive first-hand information about current products, services, references and worthwhile industry insights.

The Eagleburgmann Group

Sealing technology for plants and machines

EagleBurgmann is one of the worldwide leading providers of industrial sealing technology. Mechanical seals, seal supply systems, magnetic couplings, carbon floating ring seals, expansion joints, gaskets and packings as well as comprehensive services are used wherever reliability and safety are needed.

Mechanical seals and more

Sealing technology by EagleBurgmann is used worldwide in oil and gas industries, refineries, the petrochemical, chemical, and pharmaceutical industries, food processing, energy, water, mining, paper, aerospace, and other industries. Close to 5,800 employees provide their ideas, solutions, and commitment so that customers can rely on our sealing technology.

What makes us stand out is our excellent quality, great innovative capacity, and an extensive product portfolio for nearly all industrial processes and fields of application. Our product portfolio includes everything from mechanical seals and seal supply systems to magnetic couplings, carbon floating ring seals, expansion joints, and gaskets and packings as well as comprehensive services. Since we are part of the German Freudenberg and Japanese EKK group, we have all the necessary resources for a firmly based reliable partnership.