HR

HR

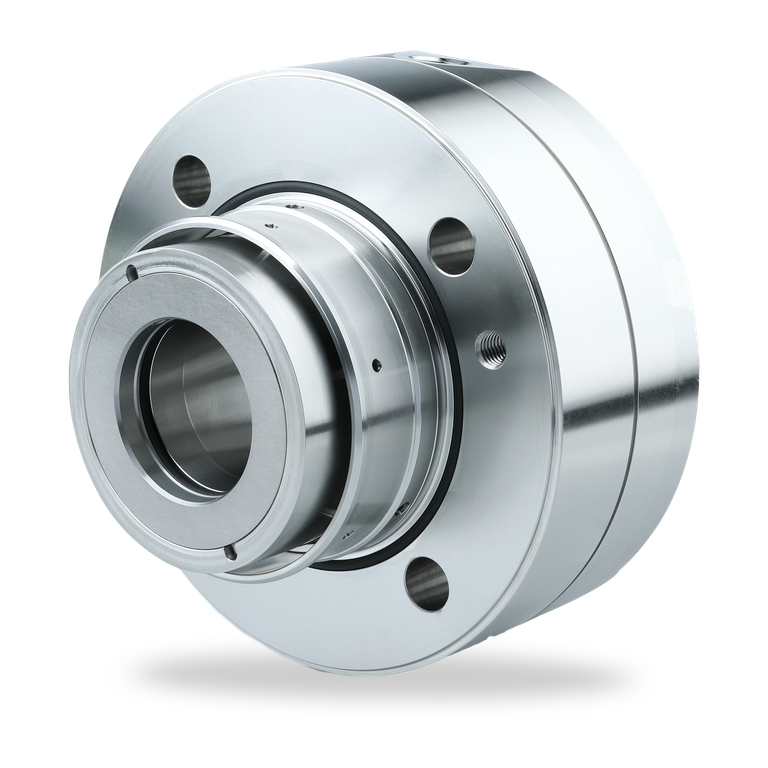

| Item | Part no. DIN 24250 |

Description |

| 1.1 | 472 | Seal face |

| 1.2 | 520 | Sleeve |

| 2 | 412.1 | O-Ring |

| 3 | 474 | Thrust ring |

| 4 | 477 | Spring |

| 5 | 475 | Seat (G11) |

| 6 | 412.2 | O-Ring |

| 7 | 412.3 | O-Ring |

| 8 | 441 | Housing |

Direction of installation: - from the impeller side HR10 - from the bearing side HR11

HR

Features

- Single seal

- Balanced

- Independent of direction of rotation

- Multiple springs stationary

- Seat rotating

- Seat arranged directly behind the impeller

- Spring protection sleeve

- Variant with cylindrical spring and acc. EN 12756 (HRZ1) available

- Variant as cartridge with/without guide sleeve for application with/without quench (HR2, HR3)

- Dual seal as cartridge unit (HRKS-D) available

Advantages

- Especially for application in solids containing media without external flush or internal product circulation. Solids content 40 % (single seal) and 60 % (double seal)

- Operation under vacuum without seat locking possible

- Pumping screw for increased circulation available

- Springs are protected from product and leakage

Materials

Seal face: Silicon carbide (Q1, Q2)

Seat: Silicon carbide (Q1, Q2)

Seat: Silicon carbide (Q1, Q2)

Standards and approvals

- EN 12756

Recommended applications

- Process industry

- Oil and gas industry

- Refining technology

- Chemical industry

- Power plant technology

- Pulp and paper industry

- Water and waste water technology

- Mining industry

- Sugar industry

- Cement industry

- Lithium

- Contaminated, abrasive and solids containing media

- Sewage water pumps

- Dredger pumps

- Oil sand extraction

- Suspension pumps of flue-gas desulphurization plants (FGD)

Notes

Direction of installation:

- From the impeller side: HR10

- From the bearing side: HR11

Product variants

HR2

Cartridge-type single seal with guide sleeve (Item no. 2) for use with quench. Insert (Item no. 1) either metal or silicon carbide.

Cartridge-type single seal with guide sleeve (Item no. 2) for use with quench. Insert (Item no. 1) either metal or silicon carbide.

HR3

Cartridge-type single seal. Insert (Item no. 1) either metal or silicon carbide. Optional without maintenance rinsing.

Cartridge-type single seal. Insert (Item no. 1) either metal or silicon carbide. Optional without maintenance rinsing.

HRKS-D

Double seal in cartridge design for operation in barrier or buffer pressure (does not open if barrier pressure fails), available alternatively with a pumping screw for a higher rate of circulation. Torque transmission e.g. by shrink disk.

Double seal in cartridge design for operation in barrier or buffer pressure (does not open if barrier pressure fails), available alternatively with a pumping screw for a higher rate of circulation. Torque transmission e.g. by shrink disk.

HRZ1

Single seal with cylindrical spring and type G76 seat. For installation in covers with installation dimensions according to EN 12756 B or U. Installation length l11 corresponds to max. l1k. Intermediate sizes on request.

Single seal with cylindrical spring and type G76 seat. For installation in covers with installation dimensions according to EN 12756 B or U. Installation length l11 corresponds to max. l1k. Intermediate sizes on request.

Similar products

SHI300

- Robust seal design - suitable for demanding light hydrocarbon applications

- Compact cartridge seal - can be fitted in older pumps with small seal chambers

- Unpressurized inboard seal with a high pressure-non contacting containment seal on the outboard – fully-rated to pipeline pressure

- Stationary spring loaded unit

- Balanced primary seal faces - in materials with high thermal conductivity and strength

- Multi-point injection - uniform heat distribution

- DiamondFace® technology optional

SHI366

- Robust seal design – especially for demanding crude oil applications

- Compact cartridge seal for small seal chambers

- Single unpressurized seal with containment high-pressure throttle design

- Stationary spring loaded unit

- Balanced seal faces in materials with high thermal conductivity and strength

- Inserted seal face

- Multi-point injection of the flush fluid optional

- Seal faces can be equipped with lubrication enhancing hydropads and/or DiamondFace technology